Malaysia Should Look At EV Battery Recycling Business

It is too late to look at EV battery manufacturing.

Let’s face the facts, Malaysia has missed the boat on electric vehicle (EV) production and also the manufacture of EV battery. Yes, there are ‘people’ who are still flying the flag claiming to be working hard to bring electric vehicle technology and manufacturing to Malaysian to elevate our knowledge and expertise in this new field of mobility.

Well, it has been clear over the past year that Thailand, Indonesia and even Singapore has overtaken us many times over and Malaysia stands as an automotive dumping ground for some as they are allowed to ‘dump’ sub standard vehicles on unsuspecting buyers who are left with little choice.

However, There Is More

By 2030 there will be over 6 million EV battery packs retiring from electric vehicles per year, according to IDTechEx’s latest report named Second-life Electric Vehicle Batteries 2020-2030.

So Here Is The MOU You Should Be Signing

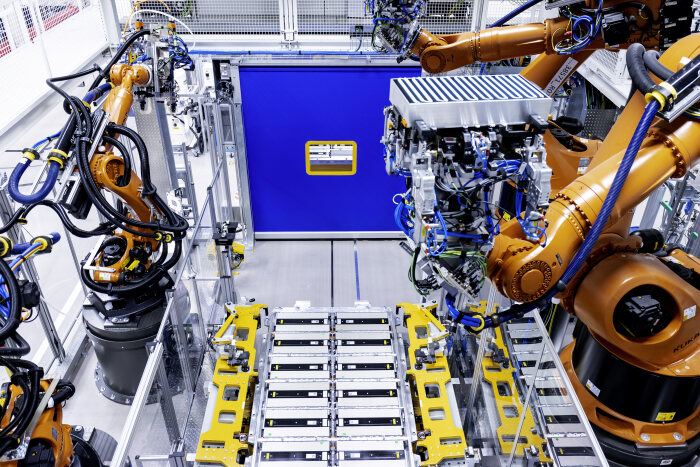

The EV Battery sustainability and stewardship is an important part of the electric vehicle industry and supply chain. It is critical to consider the waste management of electric vehicle batteries now in order to prepare for increasing future volume.

There are different ways a battery can be managed, and different applications of waste management are considered for faulty, damaged, or the end-of-life EV battery. Depending on the reason for retirement from a vehicle, a battery may be refurbished, repurposed, or recycled.

Typically, barring a collision or mechanical defect, batteries reach their end of life at 80 percent of their initial capacity.

Regulation restricting the transport of lithium-ion batteries nationally and internationally will influence resource recovery in the sector. Markets with stronger electric vehicle uptake, such as the European Union, China, and the United States, have started to implement policies to regulate battery end of life. Soon ASEAN will need it.

Policy to stimulate industry growth and a circular lithium economy will be necessary to provide certainty to investors. As it is widely accepted that stockpiling or transporting lithium-ion batteries are not viable options in the long term, management of end-of-life electric vehicle batteries will require regional solutions.

Refurbishing

In a refurbished battery, the functioning modules and cells are used for application in another electric vehicle battery. This is often the use case for factory faulty batteries, where the battery can be easily recovered by a carmaker and has not been damaged or discharged. For example, Tesla and Nissan offer refurbished battery packs for warranty replacement of original battery packs in electric vehicles.

Repurposing

In a repurposed battery, the battery’s remaining capacity is reused for a secondary application, such as stationary energy storage. A battery must undergo several processes to be safely used for a secondary application. Carmakers are investing in repurposing opportunities to give them control over the secondary use applications and to ensure they are reliable and financially viable.

Malaysia should be looking at the emerging industry for electric vehicle battery repurposing. Yes, it may not be as glamorous as EV manufacturing and assembly or as popular as EV battery manufacturing which is what some government agency want in their portfolio but this is as important and as technical as any other part of the EV value chain.

So, who will be the first to stand up and say yes to this!