A simplified guide on the semiconductor shortage that is (currently) the biggest headache for the auto industry this year.

Automakers really can’t seem to catch a break in recent times.

After the Covid-19 pandemic that ravaged the world last year saw new car sales plummet by a significant margin, many in the industry were hoping for 2021 to be the year in which sales rebounded back to the good old days. This new year however looks to not to have panned out exactly the way the automakers hoped.

That is because automakers, and in fact the manufacturing industry, are currently plagued with yet another major catastrophe. A catastrophe which stems from the shortage of a very crucial component for all modern technology these days — the semiconductor.

![]()

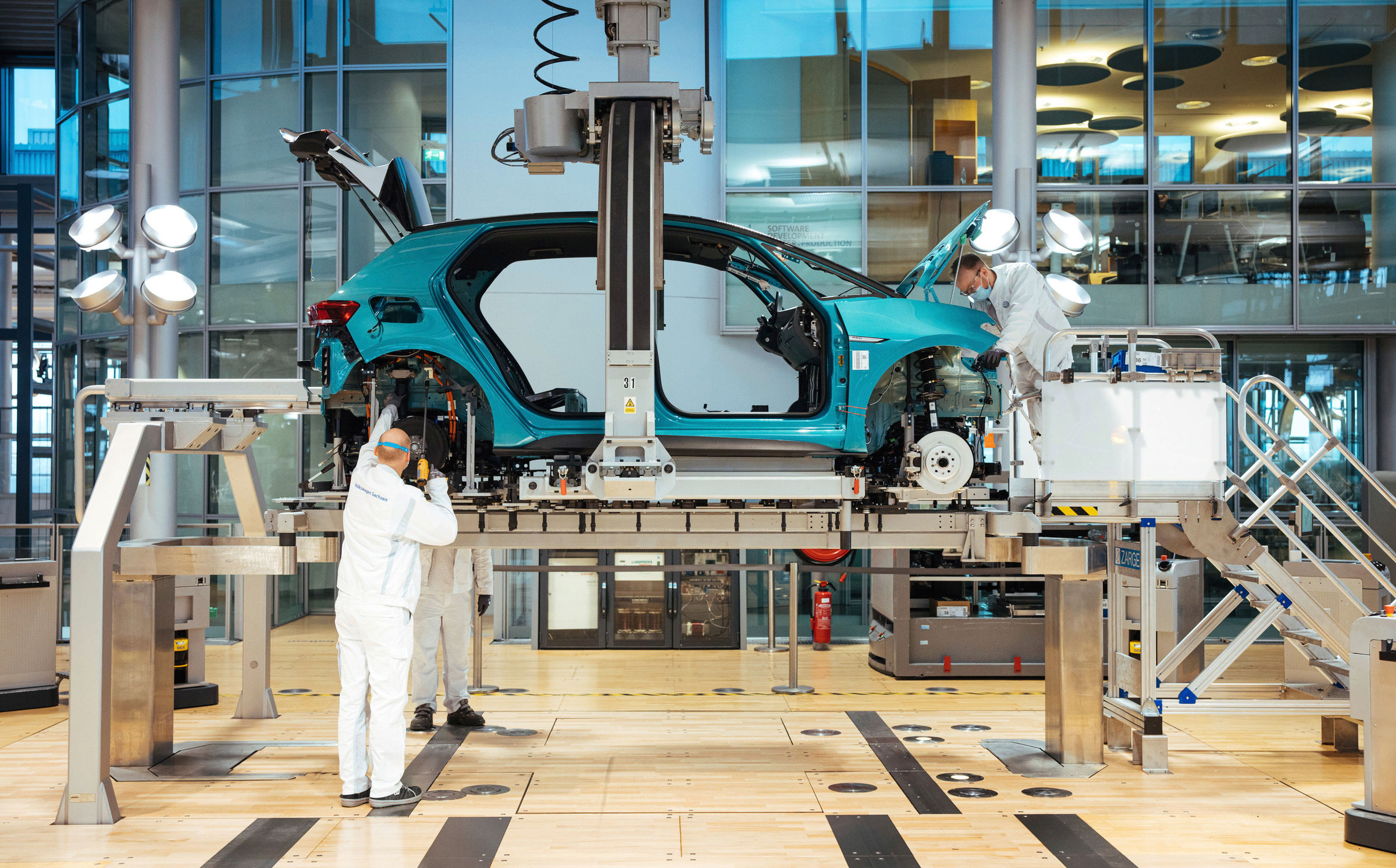

So despite new car sales seem to be recovering heading into this year, many automakers can’t actually get the cars to the customers because this semiconductor shortage is causing auto production to grind to a halt across the world. Such is the case then of the increasing number of headlines regarding auto plants which are now being forced to sit idle for weeks, or even months with no end in sight.

While this global production catastrophe is a rather complex one that involves many factors and many international players, the gist of this situation the world is currently facing however can be summarised somewhat succinctly by just answering three(-ish) basic questions. Which, as it happens, is exactly what that has conveniently been written out down below.

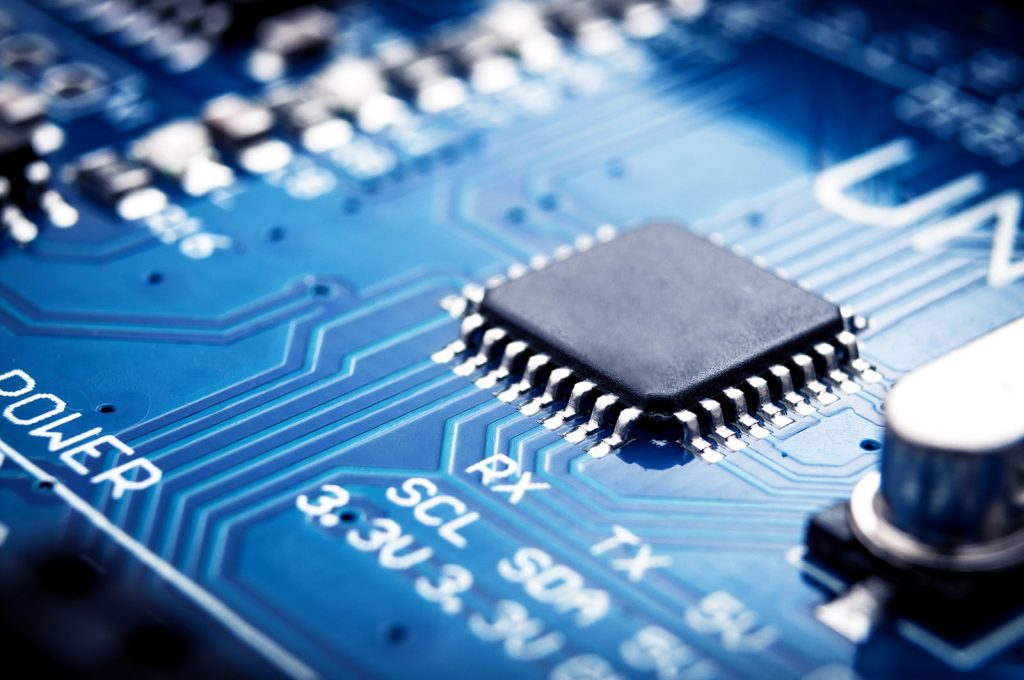

What is a semiconductor and what are they used for?

To totally avoid the risk of getting too science-y here, the simplest way to think of a semiconductor is by its most popular silicon form. Now with the word silicon, it thus should need no further explanation that this material is widely used in transistors, or its more advanced (and more commonly known) form — the microchip.

Why is there currently a semiconductor shortage?

Now without opening the geopolitical can of worms here, the main reason on why the world is currently in this production catastrophe is rather simple. And that is simply because worldwide semiconductor demand is currently vastly outstripping supply.

Focusing solely on cars at the moment, it is clear to see that the new cars these days are getting more and more technologically advanced. All these multiple screens and advanced active safety/autonomous driving tech that are commonplace in current cars therefore require more processing power to sustain those advanced features, which in turn call for more semiconductor chips.

The rapid shift to EVs has further exacerbated this problem. That is because, according to KPMG Japan at least, EVs to use roughly twice as many of these semiconductor chips as compared to conventionally-powered cars.

Then again, it is unfair to pin the blame solely on EVs or modern cars, as the biggest problem here has much to do also the sheer number of new cars, electric or otherwise, that are rolling off production lines these days. Last year not withstanding, auto production in recent years has skyrocketed to the highest ever levels in all of time.

Additionally, aside from everyone rushing out to buy new cars, our collective consumerist tendencies also went into overdrive last year when everyone stuck at home was buying more tech gadgets (smartphones, tablets, TVs, computers, gaming consoles etc.) than ever before, just to keep occupied, connected and entertained throughout the pandemic. All of these aforementioned products call for a whole lot of semiconductors, and has thus further put the strain on an already overloaded supply chain, thereby getting us to where we are now.

![]()

What is everyone doing about it?

Presently, the main course of action that many automakers like Mazda and Toyota are taking is just to shut down its factories and scale back the production of its new cars for the time being in an attempt to conserve its existing supply of chips. Of course, there has also been reports of some dealmaking going on behind the scenes, with automakers appealing to both chip suppliers and governments for a solution.

In essence then, this production problem here is capitalism at its finest, as automakers are currently duking it out with consumer electronics giants to secure a steady supply of chips for its new cars. Sadly for the automakers however, the consumer electronics giants do seem to have an upper hand in this fight because not only do they have a larger volume of orders (the annual smartphone market alone is more than 1 billion devices, compared with fewer than 100 million cars), but automakers are also less willing to bid up the chip prices due to car production being an inherently lower-margin business than consumer electronics.

This all therefore means that automakers might just have to take the inevitable losses from this semiconductor-induced production slowdown by the chin. A loss which is expected to be amount upwards of $61 billion in the auto industry alone.

Final Thoughts

At this point, some might draw the parallels of this semiconductor shortage to the vaccine production and rollout debacle the world is currently also facing, whereby it is every country (or in this case auto manufacturer) for itself. Then again though, this supply chain issue is actually more analogous to the imminent global food and water crisis.

Unlike the semiconductor shortage crisis however, where semiconductor production is slated to stabilise sometime within the latter half of this year, it unfortunately does not seem to be the case with bigger environmental issues like overfishing or the rapidly diminishing clean water supply. This semiconductor shortage crisis should therefore serve an wakeup call then towards need for innovations and regulations in regards to a more sustainable lifestyle.

We may be able to live with a six-month delay in getting new car or a new phone. The same could not be said though about living in a world with a six-month delay in obtaining a fresh water supply.