Nissan Gives Used EV Batteries A New Lease Of Life

Nissan embraces the mottainai concept on used EV batteries for a range of innovative, eco-friendly applications.

If there is one main environmental argument to be made against the new crop of electric vehicles, it will be the fact that they are not really much more environmentally friendly than its fuel-burning counterparts.

Despite having zero tailpipe emissions, the manufacture of an EV is actually a whole lot more energy and emissions intensive than its engine-driven brethren. In fact, according to a recent study by Polestar, it would take approximately 3-5 years of normal driving to offset the environmental damage incurred for the production of the EV over its internal combustion equivalent.

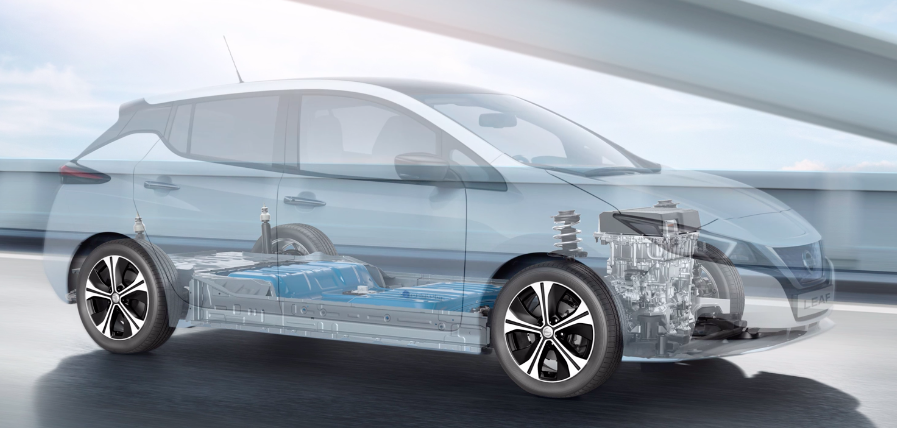

Much of this environmental impact of an electric car, especially the battery powered types that are increasingly commonplace in the automotive industry these days, is down to the manufacture of the batteries themselves. That is not only because the mining of rare earth metals needed to make the drive battery a very environmentally damaging task, but the production of the batteries too use more energy than knocking together a fuel tank, which is in essence just two sheets of steel pressed together.

Moreover, another environmental issue that arises with EVs is the issue regarding the disposal and recycling of those batteries. When these batteries eventually do not hold charge anymore, getting rid of these heavy, toxic and potentially hazardous lump of dead weight are also undoubtably more complex and energy intensive than say, a fuel tank.

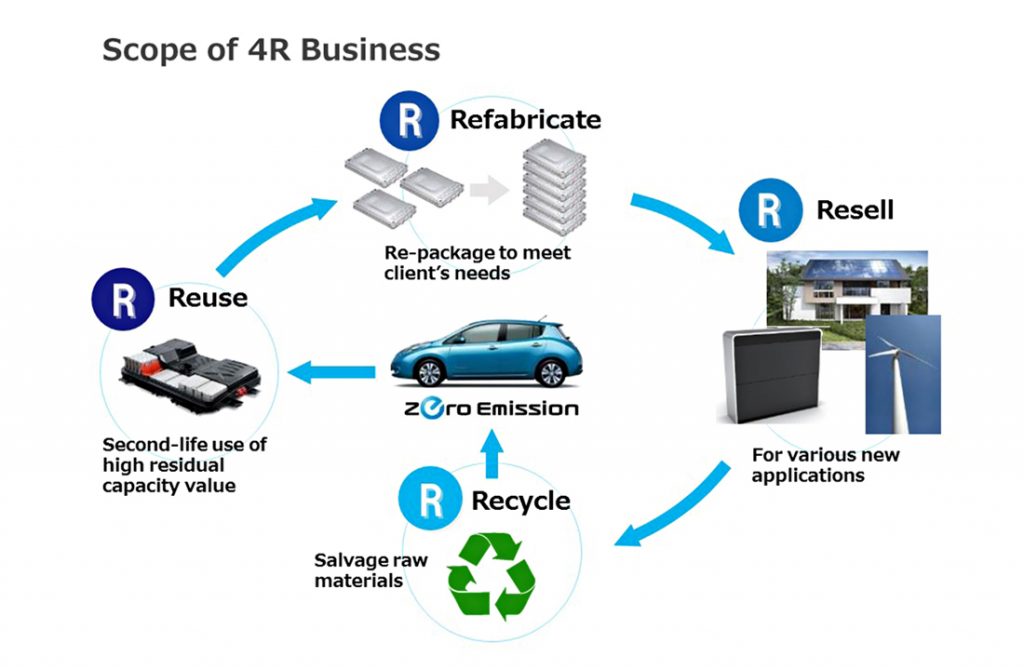

Happily however, some automakers have been taking the step to address this latter issue with their EV batteries when they do reach the end of their useful lifespan. Nissan, for instance, have partnered with Sumitomo Corp. for a while now in the running of 4R Energy Corp, a Japanese company that develops technology and infrastructure to refabricate, recycle, resell and reuse the batteries in its EVs.

Having been in operation for nearly 10 years already, this battery recycling effort by Nissan has the aim to give these cells a new lease of life, instead of simply scrapping them once done with powering a LEAF. Essentially the embodiment of the quintessential Japanese concept mottainai (waste nothing), this operation therefore allows for these used batteries to gain extra value beyond what they would usually be expected to deliver during their normal lifetime, which in turn further decreases its impact on the environment.

Just to give a taste of how this whole battery recycling operation puts these EV batteries into good use, these used battery packs have been adapted to power industrial machinery like forklifts. Moreover, some particularly top-grade cells may even make it back into ‘new high-performance battery units for a new EV’.

What is perhaps the most interesting of 4R Energy’s EV battery adaption applications however is being used as large stationary energy storage and backup power supply solutions. While a not a new idea in itself, having a used battery (that would otherwise been scrapped) to capture surplus electricity generated during the daytime by solar panels, which then powers the building during the night or during a power outage, is an incredible one-two punch of environmental-friendliness.

Additionally, 4R Energy’s innovative battery management system has made it possible for these old batteries to capture for wind and solar energy, which is then used to power charging network to support a fleet of all-electric vehicles. So in essence then it is the act of charging the current fleet of EVs with the batteries from the previous fleet.

According to current 4R Energy Corp CEO Eiji Makino, aside from the environmental benefits to giving these used batteries a new lease of life, there is also an financial benefit to EV buyers too as there is now a greater demand (hence price tag) for these depleted batteries. Instead of just being treated as scrap, this demand for used batteries therefore makes for a nice end-of-life return on investment which can go some way to offset the high cost of electric vehicles these days.

Taking into consideration the already low running costs typically associated with an EV, these innovations here could actually make electric car an even more financially lucrative option than it already is, not to mention its associated environmental benefits. If only that battery production process itself would be a cleaner, greener affair however…

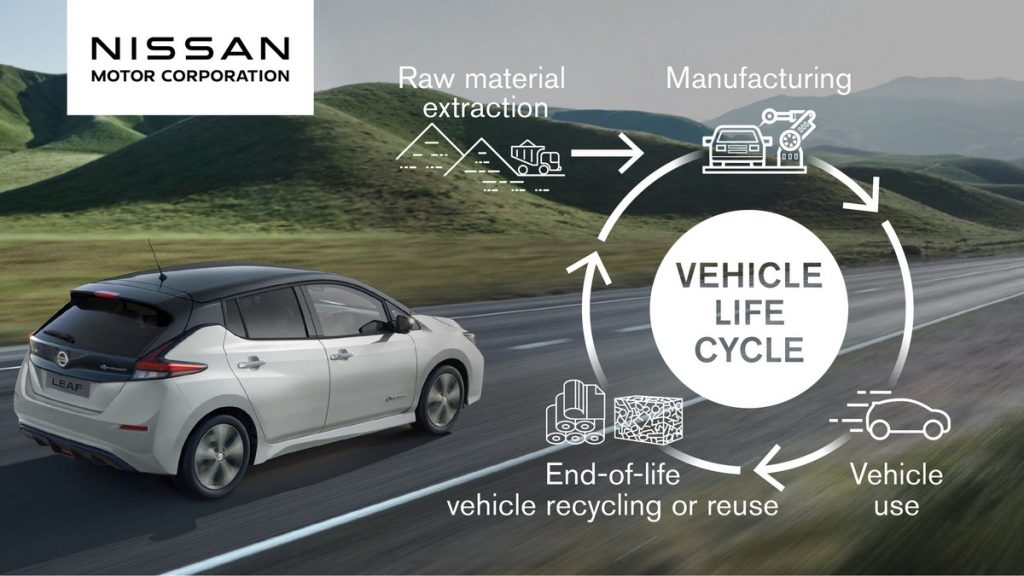

PRESS RELEASE: Designing, developing and engineering an electric vehicle is all about sustainability. After all, over their lifetime, EVs are much more environmentally friendly than traditional vehicles. However, when Nissan engineers were drafting the plans for the first-generation all-electric LEAF, they had a key insight: Developing electric cars had to be about more than vehicle performance. This new technology had to become an integral part of how our world works. become an integral part of how our world works.

Today, this means breakthroughs like Nissan’s Blue Switch project, which turns electric cars into clean, quiet and mobile emergency power supplies in the aftermath of natural disasters. Already from the very beginning more than a decade ago, the team at Nissan was thinking how one of the most crucial parts of an EV – its battery – could play a role well beyond the lifetime of the car it powers.

That’s why – already several months before the very first LEAF came to market in December 2010 – Nissan partnered with Sumitomo Corp. to set up 4R Energy Corp. Its purpose: develop the technology and infrastructure to refabricate, recycle, resell and reuse the batteries in Nissan EVs – not for their scrap value, but to power other things.

Eiji Makino has been involved with 4R Energy since its very beginning and became its CEO in April 2014. He’s passionate to find solutions that extend the environmental and economic value of EV batteries. “We knew that when it came to an EV, the recycling solution had to be much cleverer than the norm and have distinct benefits for EV owners,” Makino says. “Simply recycling an old car for scrap metal wouldn’t be good enough.”

It took quite some time for 4R Energy to develop the right technologies and concepts. Then again, they had plenty of time, because EVs like the LEAF and their batteries are remarkably resilient. Now that some of the LEAF batteries have indeed come to the end of their useful life in a car, 4R is ready to process them. The result: the batteries instantly gain extra value beyond what they would usually be expected to deliver during their normal lifetime.

When an old EV battery reaches the 4R factory, it is first graded. Sometimes, the battery components are as good as new; they get an “A” grade and can be reused in new high-performance battery units for a new EV. With a “B” grade, the batteries are powerful enough for industrial machinery like forklifts and large stationary energy storage. Deployed in a home or commercial facility, for example, they can capture surplus electricity generated during the daytime by solar panels and then power the building during the night. Even the components of a battery that gets a “C” grade can still be put to use – for example in units that supply backup power when the electric grid fails, say at grocery stores that must have their refrigerators and lights running even during a power outage. The engineers at 4R Energy estimate the recovered batteries have a life span of about 10 to 15 years, dramatically extending the usefulness of EV batteries and reducing their overall carbon footprint.

Makino has another and just as important argument for recycling EV batteries: Most electric cars are still more expensive to produce and buy than traditional cars with internal combustion engines. That is more than outweighed by the lifetime benefit of EVs, of course, because owners can typically expect lower maintenance costs and far lower “fueling” costs. With Nissan and 4R technology, however, the owners of electric cars may find that the battery in their old car could be a significant asset. By creating demand for batteries that are past their useful life, 4R helps bring down the total cost of ownership for electric vehicles even more. Owners don’t have to sell their old car just for scrap but can get much higher value for its battery, which results in a nice end-of-life return on their investment.

Energy keeps finding new ways to refabricate, recycle, resell and reuse EV batteries. On Yumeshima, a manmade island in western Japan’s Osaka, a solar farm is using 16 lithium-ion EV batteries to cope with energy fluctuations and store its energy output.

On Koshikishima, an island off the coast of southwestern Japan, 4R Energy has created an innovative battery management system that makes it possible for wind and solar energy to power the charging network that supports a fleet of all-electric vehicles. It’s the first of its kind and makes an important contribution to the goal of the 5,000 residents to make Koshikishima an “eco island” with zero CO2 emissions.

The company is also developing battery systems that help integrate solar power, local battery storage and the electricity in EVs – and can be used as a home’s emergency power supply. Another use case are the batteries for the automated guided vehicles that are becoming ever more important in modern factories and warehouses.

Ten years after the launch of the first all-electric Nissan LEAF, Makino is finally seeing his original vision come true. His team of engineers is giving EV batteries a second life, which makes electric cars affordable and more attractive to buy, and delivers true sustainability. Always ahead of the curve, 4R Energy is now putting everything in place to provide the same “4R” support – recycle, refabricate, reuse, resell – for the next generation of electric vehicles from Nissan, starting with the new all-electric Ariya. Nissan is planning to launch a whole range of new all-electric car models. The research and development by 4R, which was 10 years in the making, is finally paying off, for the better of electric car owners and the planet.