Porsche Plans To Use Sustainable Aluminium For Its Future Cars

Porsche is working together with Norwegian aluminium company Hydro to make this possible.

In an effort to further its green auto-making endeavours, Porsche has recently announced that it is to go further in its collaboration with Norwegian aluminium company Hydro to develop a more environmentally-sustainable aluminium for use in its cars. Following on from its initial partnership agreement last year, representatives of both companies have since contractually specified the possibility of delivering carbon-reduced primary aluminium as well as secondary aluminium with a high proportion of recycled material.

Within their technical collaboration, Porsche and Hydro are also currently testing where aluminium with an even higher proportion of recycled material can be used. The sports car manufacturer is working towards a net carbon neutral value chain of its newly produced vehicles in 2030, with aluminium being considered an important integral aspect of this green goal.

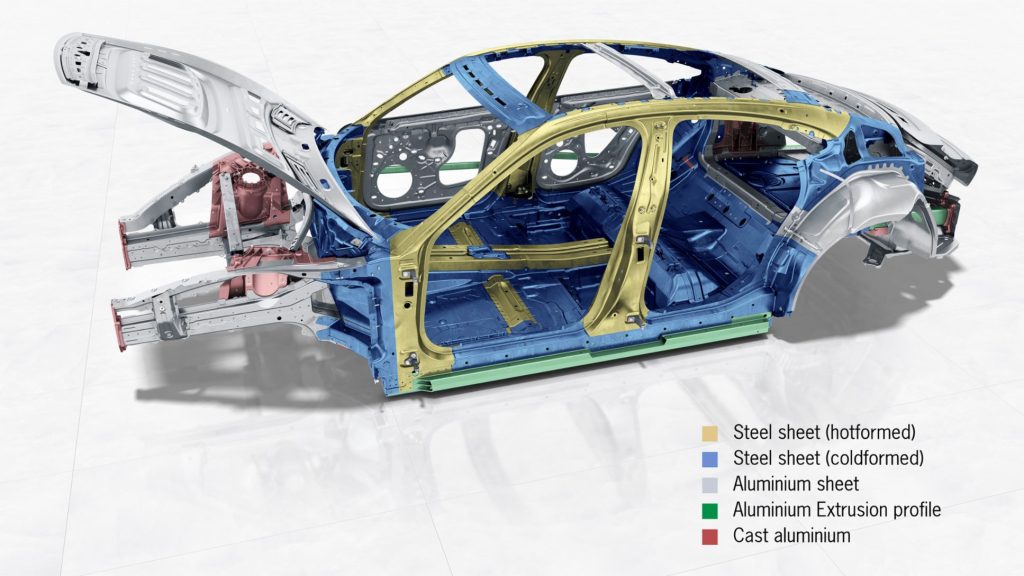

As a lightweight material, aluminium is playing an increasingly important role for electric cars in particular. For example, it makes up around 30% of the total weight of the Taycan. Apart from the front and rear aprons, as well of the entire shell of the aforementioned EV sports sedan is made of aluminium.

For widespread use in its sports car production, Porsche and its suppliers specified that it requires access to carbon-reduced aluminium with an ecological footprint of less than 4 kg of CO₂ per kg of aluminium. Renewable energy will be used in the production of this raw material, with Hydro (as the company name implies) primarily using hydro power in generating the electricity used to produce the primary metal in Norway.

According to the Norwegian aluminium maker, the use of renewable energy reduces the carbon footprint of the light alloy by about 75%, compared to the global average of primary aluminium production. The carbon footprint specifies the quantity of greenhouse gases released and refers to all the emissions from the mining to the resulting raw material.

The two companies are not only aiming to further reduce these total emissions, but they also want to increase their use of secondary materials from post-consumer scrap. These are materials disposed of by private households or commercial, industrial and institutional facilities after a product has been used.

It is expected that by 2027/2028, Hydro will be supplying carbon-reduced aluminium with a recycled proportion of at least 75 per cent. Porsche and Hydro are also testing the areas of the car in which aluminium with an even higher proportion of recycled material can be used.

Just to interject here with a science note too, the strong ionic bonds that are inherent in aluminium oxide (aluminium ore’s natural state) sees for the manufacture of virgin pure aluminium to be an extremely energy intensive process. About 17,000 kWh of electricity is in fact required to produce 1 tonne of the material.

This high energy requirement for the production of virgin aluminium is hence why aluminium recycling is so lucrative. The recycling process uses much less energy reprocessing the aluminium than was used to produce it, with that delta to be as high as approximately 95%.

“The collaboration with Hydro is an important milestone for Porsche on our path to decarbonisation along the entire value chain,” says Barbara Frenkel, Executive Board Member for Procurement at Porsche AG. “The partnership is also making a contribution to responsible procurement, because Hydro’s aluminium supply chain is transparent.”

“Our collaboration with pioneers like Porsche supports Hydro’s ambition to change the game for sustainability in the aluminium industry. Together, in this long-term strategic partnership, Hydro and Porsche will push forward innovative solutions and business models, aiming to drive decarbonization and circularity in the automotive industry,” says Eivind Kallevik, President and CEO of Norsk Hydro.