Nissan unveils transformation plan as factories close

Under a cloud of factory closures and job losses for their factory staff and also vendors and suppliers, Nissan is issuing a statement to show its plan to prioritise sustainable growth and profitability.

Nissan Motor Co., Ltd. Has just unveiled a four-year plan to achieve sustainable growth, financial stability and profitability by the end of fiscal-year 2023. The scalable plan, involving cost-rationalization and business optimization, will shift the company’s strategy from its past focus on inflated expansion.

As part of the four-year plan, Nissan will take decisive action to transform its business by streamlining unprofitable operations and surplus facilities, alongside structural reforms. The company will also reduce fixed costs by rationalizing its production capacity, global product range and expenses. Through disciplined management, the company will prioritize and invest in business areas expected to deliver a solid recovery and sustainable growth.

By implementing the plan, Nissan aims to achieve a 5% operating profit margin and a sustainable global market share of 6% by the end of fiscal year 2023, including proportionate contributions from its 50% equity joint venture in China.

Makoto Uchida, Nissan chief executive officer, said: “Our transformation plan aims to ensure steady growth instead of excessive sales expansion. We will now concentrate on our core competencies and enhancing the quality of our business, while maintaining financial discipline and focusing on net revenue per unit to achieve profitability. This coincides with the restoration of a culture defined by “Nissan-ness” for a new era.”

The four-year plan is focused on two strategic areas, building on Nissan’s reputation for innovation, craftsmanship, customer-focus and quality, alongside an ongoing cultural transformation:

1) Rationalization: robust actions to restructure, reduce costs and improve efficiency

Actions:

- Right-sizing Nissan’s production capacity by 20% to 5.4 million units a year under the assumption of a standard shift operation

- Achieving plant utilization rate above 80%, making operations more profitable

- Rationalizing the global product line-up by 20% (from 69 to fewer than 55 models)

- Reducing fixed costs by approximately 300 billion yen

- Intend to close Barcelona plant in Western Europe

- Consolidating North American production around core models

- Closure of manufacturing facility in Indonesia and concentrating on Thailand plant as single production base in ASEAN

- Alliance partners to share resources, including production, models, and technologies

2) Prioritizing core markets and core products

Actions:

- Focusing Nissan’s core operations in the markets of Japan, China and North America

- Leveraging the Alliance assets to maintain Nissan’s business at appropriate operational level in South America, ASEAN and Europe

- Exiting South Korea, the Datsun business in Russia and streamlining operations in some markets in ASEAN

- Focusing on global core model segments including enhanced C and D segment vehicles, electric vehicles, sport cars

- Introduce 12 models in the next 18 months

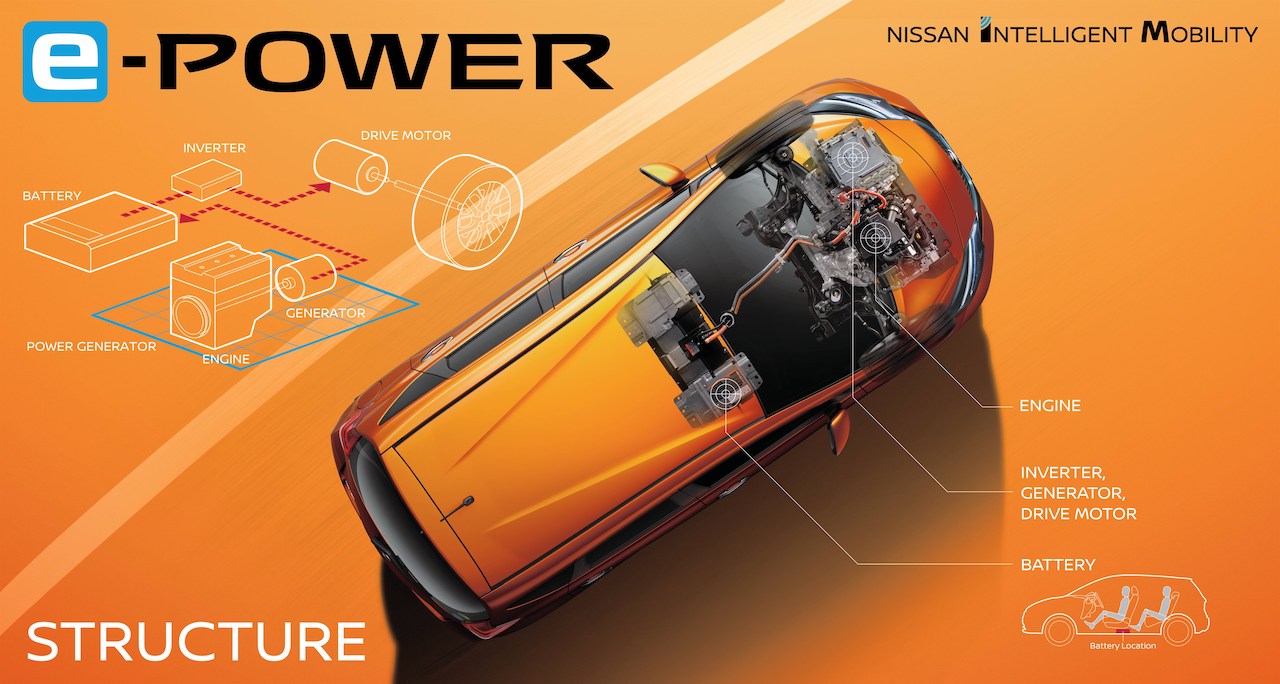

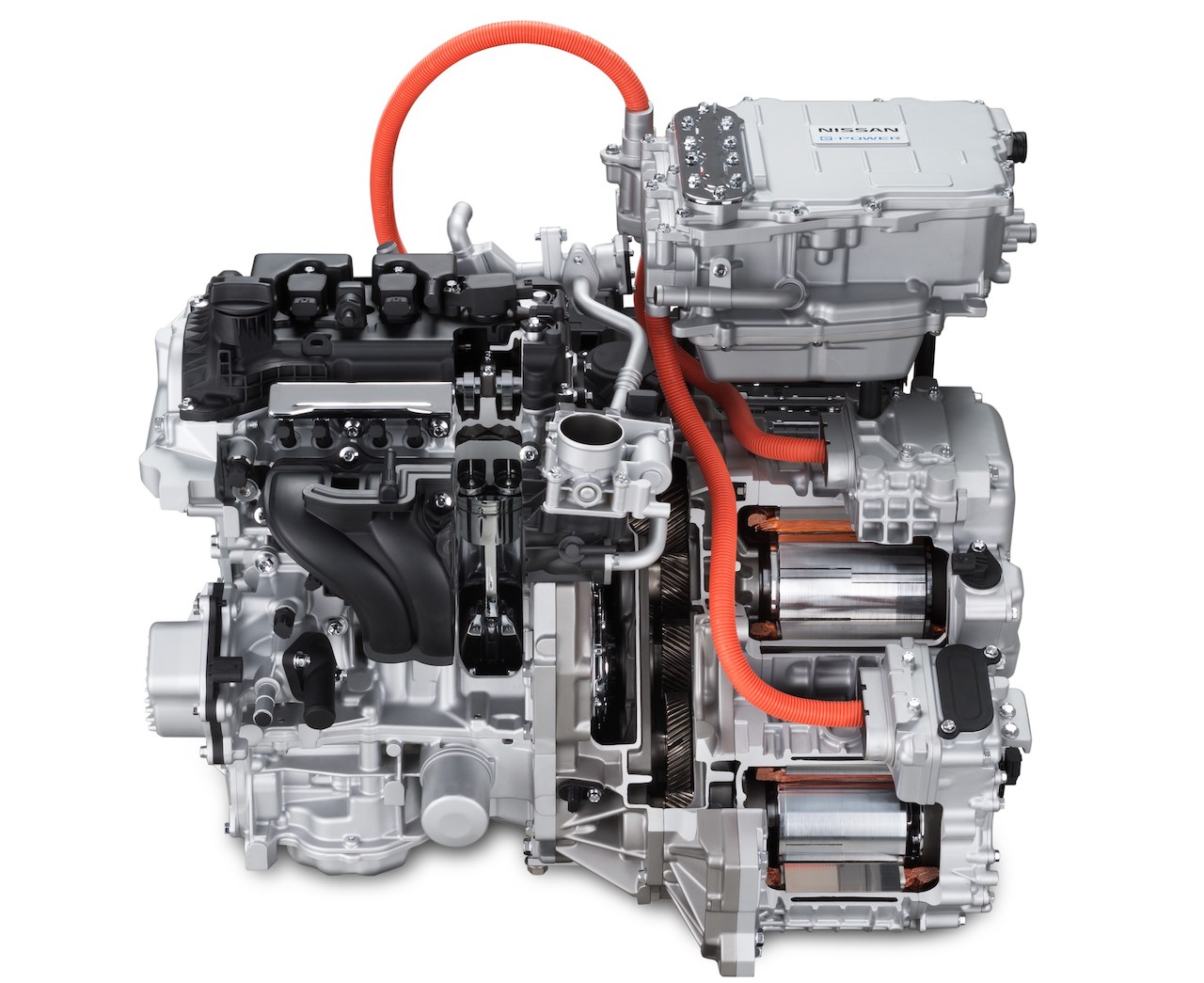

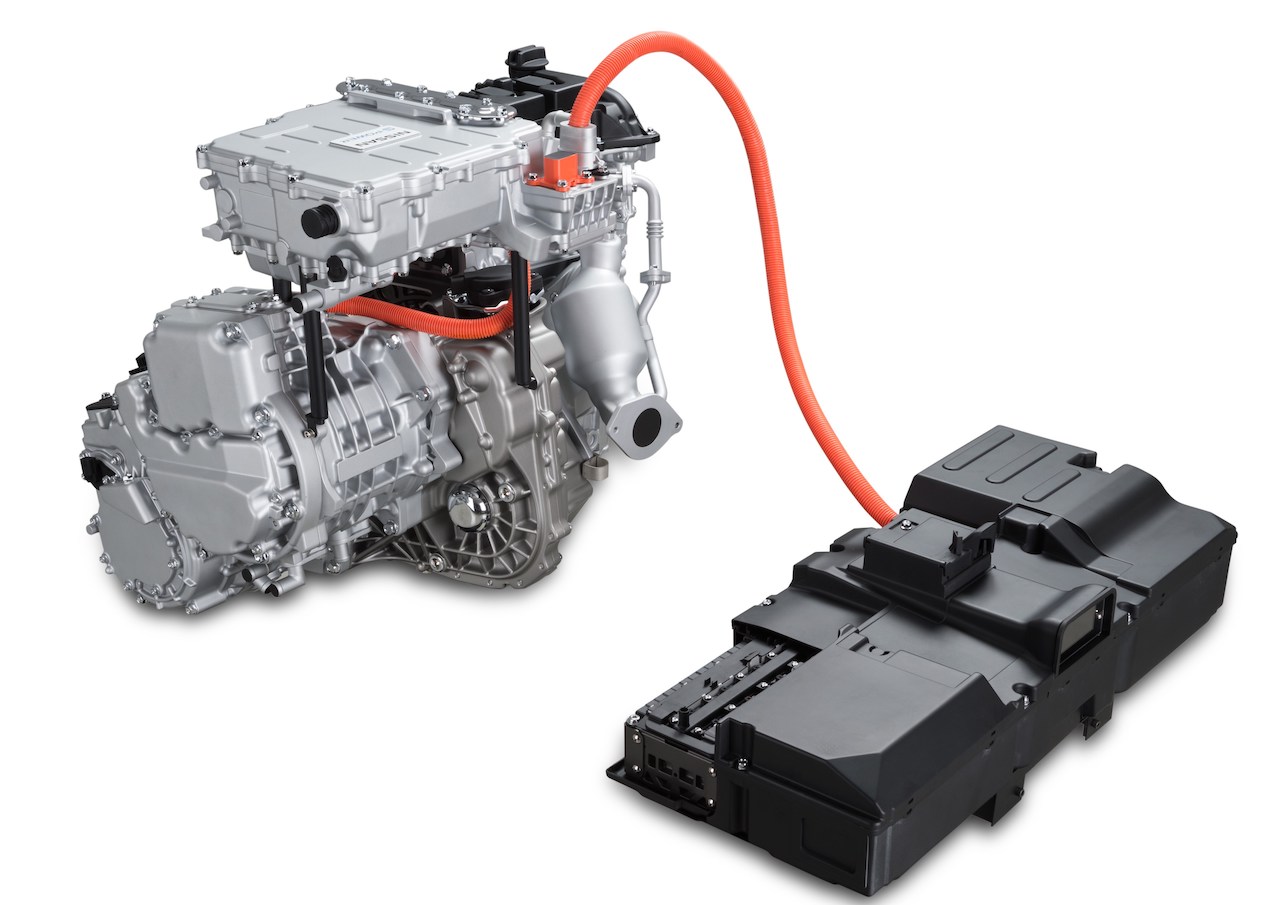

- Expanding presence in EVs and electric-motor-driven cars, including e-POWER, with more than 1 million electrified sales units expected a year by end of FY23,

- In Japan, launching two more electric vehicles and four more e-POWER vehicles, increasing electrification ratio to 60% of sales

- Introducing ProPILOT advanced driver assistance system in more than 20 models in 20 markets, targeting more than 1.5 million units to be equipped with this system per year by the end of FY23.

Uchida concluded: “Nissan must deliver value for customers around the world. To do this, we must make breakthroughs in the products, technologies and markets where we are competitive. This is Nissan’s DNA. In this new era, Nissan remains people-focused, to deliver technologies for all people and to continue addressing challenges as only Nissan can.”