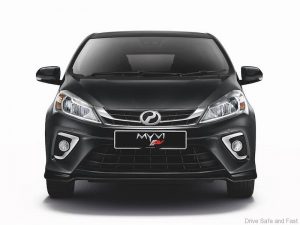

வெளியான முதல் நாள் அன்று 6,000 வரை பெரோடுவா மைவி முன்பதிவு

நவம்பர் 16 ம் தேதி தனது முதல் அறிமுகமான All-New Perodua Myvi, அதன் முதல் வாடிக்கையாளரான Permodalan Nasional Berhad (PNB) குழுவின் தலைவர் YBhg Tan Sri Abdul Wahid Omar க்கு வெள்ளிக்கிழமை முதல் விநியோகத்தை அளித்தது.

“PNB இன் குழுத் தலைவராக நான் முன்பே புக்கிங் செய்ய முதல் வாடிக்கையாளராக இருந்தேன், மற்றும் அனைத்து புதிய பெரடோவா மைவி முதல் காலை வழங்குவதைப் பெற்றேன்,” என்று Tan Sri Abdul Wahid கூறினார்.

நவம்பர் 17 அன்று காலை 8.00 மணியளவில் 6,000 அலகுகள் மொத்த புக்கிங் பெற்று, அனைத்து புதிய பெரோடுவா மைவி அதே நாளில் காலை 8 மணியளவில் விநியோகிக்கப்பட்டது. நவம்பர் 9 ஆம் தேதி மலேசியாவில் மிகுந்த விருப்பமான காம்பாக்ட் கார் நிறுவனம் ஆல்-நியூ பெரோடுவா மைவிக்கு ஆர்டர் புத்தகங்களை திறந்தது.

“பெரோடுவாவில் எங்கள் சொந்த மலேசிய வடிவமைப்பாளர்கள் மற்றும் பொறியியலாளர்களால் அழகாக வடிவமைக்கப்பட்டுள்ளது, பிரீமியம் கார்களில் மட்டுமே நீங்கள் எதிர்பார்க்கும் அனைத்து மேம்பட்ட அம்சங்கள் உள்ளன. மற்றும் ஒரு 5 நட்சத்திர ASEAN NCAP பாதுகாப்பு மதிப்பீடு கூட! “டான் ஸ்ரீ அப்துல் Wahid கூறினார்.

நவம்பர் 16 ஆம் தேதி 5 நட்சத்திரமான ASEAN NCAP தரவரிசை அதிகாரப்பூர்வமாக அனைத்து புதிய பெரோடுவா மைவிக்கு வழங்கப்பட்டது.

“எங்கள் முதலீட்டாளரான பெரோடுவாவின் சாதனைகளைப் பற்றி PNB மிகவும் பெருமையாக உள்ளது. அவர்கள் உண்மையில் தேசிய கார் நிறுவனத்தின் நிலையை தகுதி. பேராடோவில் அணிக்கு வாழ்த்துகள்! “என்று டான் ஸ்ரீ வாஹித் கூறினார்.

“மலேசியர்களையும், அரசாங்கத்தையும், மற்ற அனைத்து பங்குதாரர்களையும் நாங்கள் நன்றி தெரிவிக்க விரும்புகிறோம், எங்கள் அன்புக்குரிய Myvi அவர்களின் வலுவான அங்கீகாரத்திற்காக,” பெரோடுவா ஜனாதிபதி மற்றும் தலைமை நிர்வாக அதிகாரி டத்துக் (டாக்டர்) அமீனார் ரஷீத் சலீஹ் கூறினார்.

மைவி 12 ஐகான் ஆண்டு எமிரேட்ஸ் எஸ்.எஸ்.எஸ் மற்றும் வின் போட்டியில்’ மூன்று பரிசுப் பரிசு வென்றவர்கள் முதன்மையான உரிமையாளர்களுள் ஒருவராக இருந்தனர்.

திருமதி சின் மீ லிங் (26), திரு முகம்மது நஸ்மின் பின் முகமட் நசீர் (33) மற்றும் திரு ஓங் கோக் செங் (60) ஆகியோர் அடங்கும். அனைத்து புதிய மைவி 1.5 அட்வான்ஸ், RM55,300 க்கும் விற்பனையாகும்.

“அனைத்து புதிய புதிய பெரிடூவா மைவி அவற்றின் உரிமையாளர்களுக்கு விரைவாக வழங்கப்படுமென உறுதிப்படுத்த நாங்கள் காரின் விநியோகத்தை அதிகரிக்க உறுதிபூண்டோம். அனைத்து புதிய புதிய பெரிடூவா மையீவைப் பற்றியும், காரை ஓட்டுவதற்கு சோதனை செய்வதற்கும் நாடு முழுவதும் எங்கள் விற்பனையக விற்பனையை பார்வையிடுமாறு நாங்கள் அனைவரும் வரவேற்கிறோம், “டாட்டூ (டாக்டர்) அமீனார் கூறினார்.

முதல் தலைமுறை பெரோடுவா மைவி 2005 இல் அறிமுகப்படுத்தப்பட்டது, மேலும் 2005 மற்றும் 2017 ஆம் ஆண்டுகளுக்கு இடையே ஒரு மில்லியன் அலகுகள் உற்பத்தி செய்யப்பட்டன, இது வரலாற்றில் மிகவும் பிரபலமான பெரோடுவா மாதிரியை உருவாக்கியது. 1994 ஆம் ஆண்டு ஆகஸ்ட் மாதம் முதல் 3.2 மில்லியன் வாகனங்கள் உற்பத்தி செய்யப்பட்டது.